Platform Bed Construction Techniques – How we make solid hardwood platform beds that will endure for generations

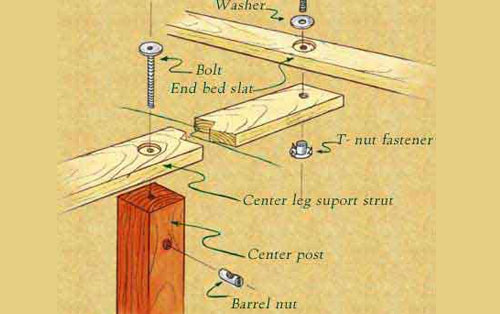

At Scott Jordan Furniture, we have produced thousands of platform beds over the past fourty years and we know from experience that our methods are sound. We prefer using a through bed bolt method to construct our platform beds. Through bed bolts are a fail-safe method of insuring a very tight mechanical connection that eliminates bed rattle, shake, and motion transfer; ensuring generations of service.

At Scott Jordan Furniture, we have produced thousands of platform beds over the past fourty years and we know from experience that our methods are sound. We prefer using a through bed bolt method to construct our platform beds. Through bed bolts are a fail-safe method of insuring a very tight mechanical connection that eliminates bed rattle, shake, and motion transfer; ensuring generations of service.

Our beds are made of solid hardwood. They are not made of plywood, particle board or any other forest product that might be referred to as “all wood construction”. We use locally sourced hardwoods, primarily cherry, walnut and oak. Our lumber is sourced primarily from the Northeast; mostly Pennsylvania and New York. All of the lumber that we use is harvested sustainably. The forests are managed to perpetuate their existence as forests and in a manner that is respectful of the larger environment.

We use only non-toxic plant oils and beeswax for our platform bed finishes. The plant oil, mostly from flax seed and cotton seed, imparts a soft lustrous yet mellow shine to the surface of the wood. It is non-toxic both to the end-user and to the craftsmen in our workshop.

Also, we only use standard hardware in our platform bed construction. All of the components can be found at a good hardware supplier. This avoids the trouble of replacing specialized furniture hardware that might be difficult to replace if lost, especially years from now.

The hardwood slats in our beds are supported by a center leg that insures that the slats will not bend and sag over time. This also provides a firm, level, foundation for the mattress. Furthermore, our bed slats are made from sound hardwood; we use a variety of woods that are suitable to the function: oak, maple, ash and sometimes cherry, according to what is currently available from our lumber supplier. In any case we select only locally sourced hardwood.

The hardwood slats in our beds are supported by a center leg that insures that the slats will not bend and sag over time. This also provides a firm, level, foundation for the mattress. Furthermore, our bed slats are made from sound hardwood; we use a variety of woods that are suitable to the function: oak, maple, ash and sometimes cherry, according to what is currently available from our lumber supplier. In any case we select only locally sourced hardwood.

pocketed straps securing bed slats prevent slats from shifting or coming loose

The spacing between the slats in normally 3.75″ using our pocketed straps that hold the slats.

canvas straps woven through bed slats allows for smaller spacing as required by some mattress manufacturers.

Alternatively we can weave a set of canvas straps through the slats creating a smaller spacing as required by some foam mattress manufacturers.

Scott Jordan Furniture platform beds are constructed one at a time allowing for a wide selection of size and designs. By employing computer controlled machinery to produce the parts one at a time very precisely, we can offer a very high degree of accurate fit with these fine hardwoods.

Need a custom leg height for underbed storage or individual size? No problem, customization possibilities of leg height can be made in our Brooklyn workshop. Contact our showroom at the number listed below for custom size quotes.

Please visit our showroom in the Brooklyn Navy Yard and work with our expert design staff to find a solid wood platform bed tailored to your desires.