We believe a good mattress should:

Provide proper spinal support, exert minimal surface pressure on the skin, and maintain a dry micro-environment around the body.

Provide proper spinal support, exert minimal surface pressure on the skin, and maintain a dry micro-environment around the body.

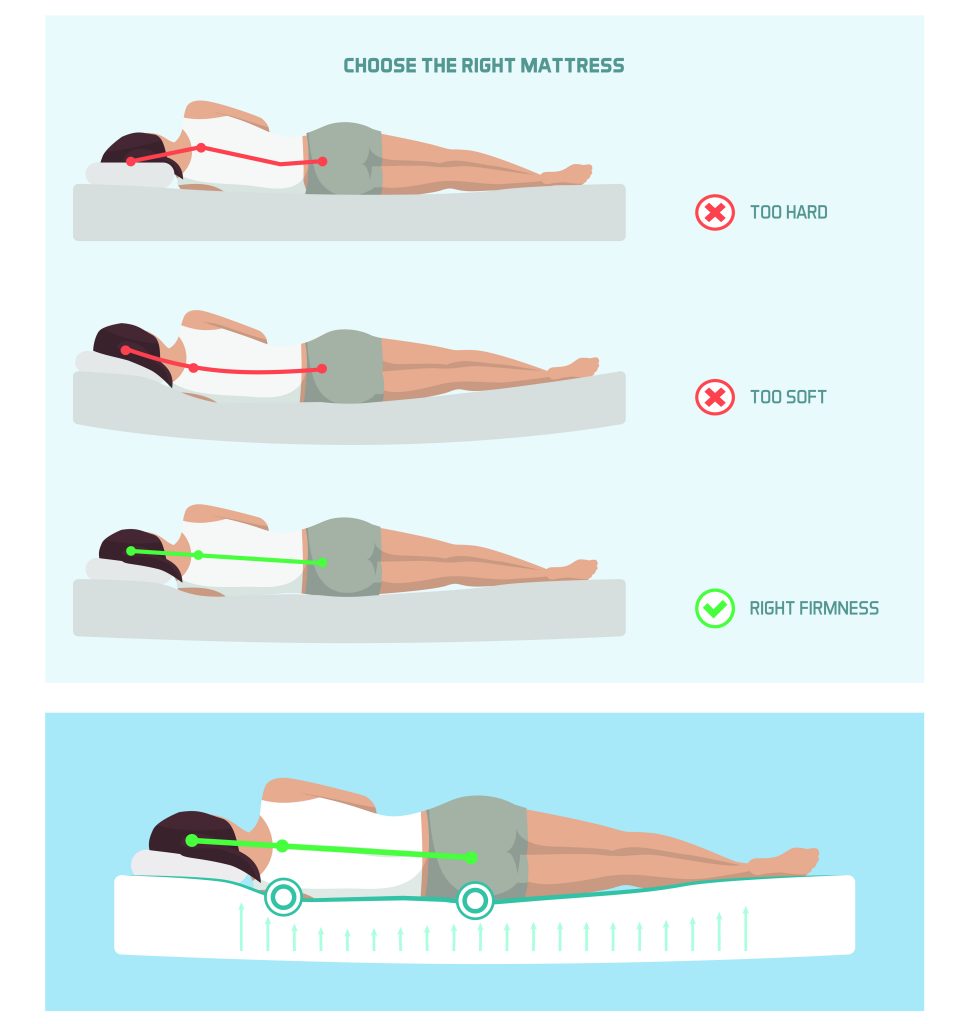

Correct sleeping ergonomics and body posture, mattress and pillow selection infographic

Many people find sleeping on their sides most comfortable. If the body is supported in a way that the spine remains straight while resting. the spine will be relieved of the pressure on the spinal discs. Relieving this pressure, allowing the spine to relax, allows the discs to re-hydrate during the night. The cartilage spinal discs are pressed and squeezed during daytime activities and need time to rest and rejuvenate. Reducing the pressure on them promotes this healing.

A common misconception is that a firm surface will provide even support for the spine. However this is not how things really work. In practice a too firm mattress will not allow the hips and shoulders to sink a bit into the surface but will thrust them upwards bending the spine – working against the need to re-hydrate the discs, allowing them to regain their suppleness. Over time this can lead to excessive wear on the discs; resulting in discomfort, even pain.

A mattress, even if properly designed and constructed, will not cure orthopedic problems. Anyone who states otherwise is promising something that they cannot deliver. A good mattress, however can promote healthy spinal hygiene that mitigates against the normal stresses delivered by everyday living.

A second objective of effective mattress design and construction is minimizing surface pressure; i..e. The pressure between the mattress and the skin. The pressure on the skin is likely to be highest at the hip and the shoulder as these areas push into the mattress surface. If this pressure exceeds a certain level ( about 29” Hg) it stops capillary flow under the skin. In an immobile individual this capillary shut-off will produce a bed sore. In a normal situation the capillary shut off will prompt a signal to the brain stem causing the individual to shift position in an attempt to restore blood flow to the affected area. Thus, high surface pressure leads to tossing and turning, and the associated brain stem activity works against arriving at and maintaining deep, restful REM (rapid eye movement) sleep.

The third important criteria to be considered is moisture and heat management in the sleeping micro-environment – the area immediately surrounding the body. It is natural to continually perspire moisture through the skin and to expel moisture in the exhaled breath. For the average person; about 1 liter per night.

The sensation of dampness is not comfortable and is not conducive to sound sleep. Usually the sensation of perspiration on or near the skin is interpreted as being hot.

Wool is a superior fiber for mattress quilting as it facilitates the wicking of moisture away from the body rendering the micro-climate closest to the body dry and comfortable. The wool is encased in our organic cotton stretch knit covers.

A second quality of wool as mattress quilting material is its fire resistance. The inherent fire resistance of wool in mattress quilting plays an important role in consumer mattress safety.

In 2008 the Consumer Product Safety Commission (CPSC) created a new set of standards for testing the flammability of mattresses, known as “open flame testing”. This more stringent testing protocol mandated that mattresses withstand a considerable amount of open flame applied against the top and sides without combustion. Mattress that are quilted with wool were found to be able to pass this testing protocol provided that Kevlar thread was used to sew the components. Unfortunately for mattress consumers (nearly everyone) the mass market mattress industry elected to address this issue in a manner less expensive to the producer (but not to the consumer). The mass market mattress produces elected to comply with the new regimen by using flame retardants in the polyurethane foam that they use for cushioning material. Specifically polybrominated diphenyl (PBDE). An internet search on this term will yield some alarming information on the properties of this chemical. Indeed it is likely that most people wouldn’t opt to be in contact with this substance give the knowledge of its presence in their (or their childrens’) mattress.

Our mattresses – made by Berkeley Ergonomics – are designed with distinct layers.

The base layer we call the support layer. Its purpose is to distribute the weight of the body and support every area evenly. The shoulder and the hip must be able to sink in a bit, so as to not create a bend in the spine and high surface pressures. The adjacent waist area must be supported independently.

An effective material to accomplish these objective is a small diameter steel coil that operates independently of its neighbors, (known in the industry as a pocketed coil). To some extent, the life of the mattress is dependent on the quality of the spring steel used in these coils.

The upper layer of our mattress is known as the comfort layer. In our mattresses this layer contains natural latex foam rubber. Latex foam is a superior cushioning material that has several advantages over polyurethane foam used in lesser quality mattresses. The chief characteristic making it a superior cushioning material is that it does not take a “compression set” as do polyurethane foams. In plain English – it springs back to its original size and elasticity even over tens of thousands of cycles. Mattresses made with latex foam comfort layers resist taking on “body impressions”. Will it last forever? No…but it will last longer than a comparable construction made with polyurethane foam and it will feel better longer.

We also offer other mattresses that have a second comfort layer made with pocketed mini coils. These mattresses offer an unparalleled level of support and comfort.

Scott Jordan Furniture is the exclusinve New York Area source for Berkeley Ergonomics mattresses. Our long experience with their products we offer a buying experience that is based on sound and personal advice from well educated, expert sales people.

We invite you to visit our showroom where we have samples of the construction and materials used in our mattresses. Only an educated consumer can make an truly informed decision that has considerable impact on their health and well-being. Our workshop and sales loft is located in the Brooklyn Navy Yard, Building 280 – 6th floor. Contact us: 212-620-4682

The cornerstone of Berkeley Ergonomics designs and philosophies is product performance. If a product doesn’t meet the highest performance standards, they simply don’t buy it.

All the design elements work together to provide:

The Cradle to Cradle® Gold Certification proves that Vita Talalay’s 100% Natural latex is the most healthy and 100% natural comfort material in the world.