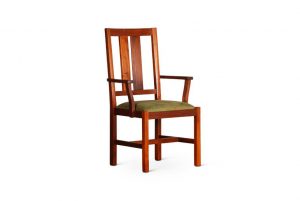

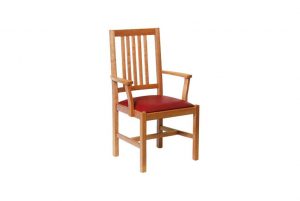

Sturdy Dining Chairs Made in Our Brooklyn Workshop

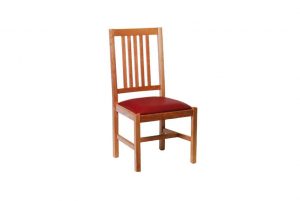

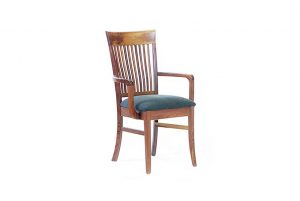

We offer a collection of dining chairs made in our own workshop in the Brooklyn Navy Yard.

We are able to produce a very sturdy chair in small quantities with the help the use of computer controlled machinery. This system of production enables us to incorporate design features that greatly add to the strength of the chair at little incremental cost.

We feel that our Brooklyn-made chairs represent a very good value in terms of price to quality.

We know from many years of manufacturing experience and from testing results that several factors determine how successfully a dining chair will withstand the pressures of daily use:

- The dining chair should use mortise and tenon construction in the seat rails and stretchers. Doweled construction is cheaper and quicker to produce but it not nearly as strong. Unfortunately the type of joints used is not readily apparent from an examination of the chair as the joints are internal. It is unrealistic to expect most furniture salesmen to know even what these terms mean. See below for example photo

- The strongest dining chairs use finger jointed corner blocks under the corners of the seat. These corner blocks should be glued and screwed into the chair rails. Fortunately this is easy to discover. Looking under the seat will reveal the presence (or absence) of corner blocks that have a comb-like shape that fits into similar shapes on the inside of the seat rail. See illustrations below for details.

- Stretchers connecting the legs that create bracing from the front leg to the back. These stretchers should also employ mortise and tenon joints.

- Compressing the tenon during assembly contributes to a very strong bond.