Essential Elements of High Quality Chair Construction

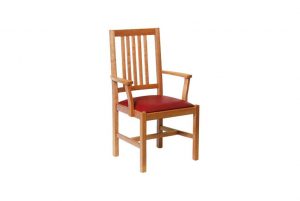

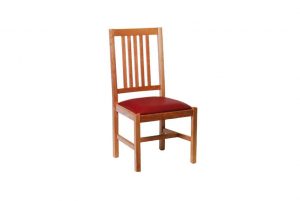

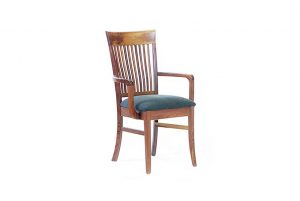

Several design and chair construction factors determine the ultimate strength of a dining chair frame.

- chair frame is made of clear hardwood free of large knots and splits.

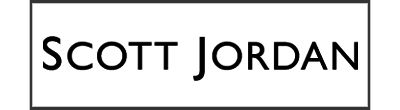

- connections between the parts are fashioned using mortise and tenon joints.

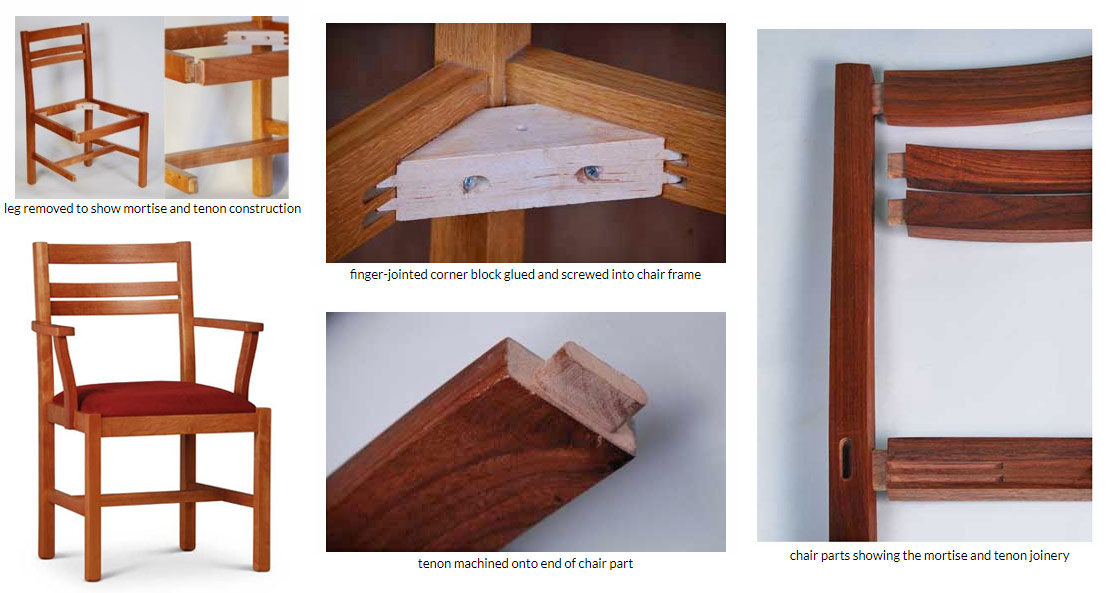

- Tenons are the oblong projections cut from the wood at the end of the part. The tenon fits into the oblong recess, called the mortise, cut from the part to which it is to joined. See photos illustrating these parts

- Mortise and tenon joints are far stronger than doweled joints. Dowels pins are round rods of wood that fit into a corresponding drilled round hole. Unfortunately it is difficult for the chair buyer to determine how the connections are made. All too often the salesperson has no idea how it is made.

- During the assembly process the tenons should be compressed very slightly before being inserted into the mortises. Wood glue is applied to the tenon surface after compression and then inserted into the mortise. The moisture in the glue will cause the slightly compressed tenon to expand to its original dimension thus creating a perfectly fit and well glued joint. The slight compression of the tenon prevents the tenon from pistoning the glue off of the surface when inserted into the mortise avoiding a glue-starved joint.

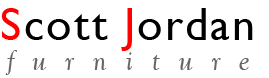

- Finger-jointed corner blocks that are glued into matching recesses in the seat rails and clamped into position with screws. We know from laboratory testing that finger jointed corner blocks are usually the most important determinant of chair strength. Fortunately the presence (or absence) of finger jointed corner blocks is easily discovered by turning the chair over and examining the construction under the seat.

- The chair construction incorporate stretchers that join the lower portion of the legs from front to back, For maximum strength these should be joined using mortise and tenon joinery as well.

All of the chairs that we make in our Brooklyn workshop incorporate these chair construction features.

We have be making chairs for well over thirty years and have studied and practiced the art with diligence. We make a very strong chair; we invite your visit to our showroom to sit down and take a look.