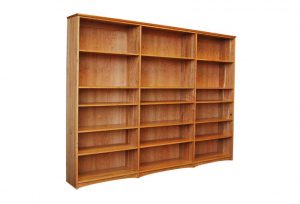

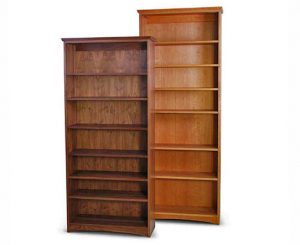

Often when one hears the words “custom cabinetry’ the image of a craftsman in a flannel shirt laboring at his workbench is summoned to mind. Our reality is quite a bit different from this image.

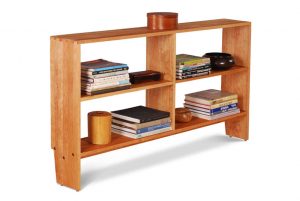

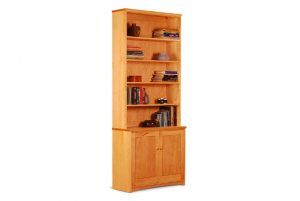

Our version of custom cabinetry involves computer aided design and manufacturing techniques that allow us to readily modify and produce almost endless variations and combinations of elements that create cabinetry solutions to fit the need of our clients.

The company started producing furniture in 1980. Indeed for the first twenty years we produced solid hardwood furniture essentially by hand. The process was much as many people image how furniture is made using saws, planers and other woodworking machinery that would be familiar to anyone who might have seen a high school wood shop in their youth.

In 1999 we purchased computer controlled machinery to perform much of the work of actually cutting the wood to shape, fashioning the joinery and making the drawers. The design side was accomplished using solid modeling programs that integrate with the production machinery. Over the years we have develop a large library of flexible computer code that allows us to readily alter the dimensions and features of constituent furniture parts. This process enables us to readily produce variations of existing parts and thus, when necessaly completely unique furniture.

In the 19th century much industrial production was focused on mass production; making a lot of the same thing over and over. One main reason was that often machine processes involved a lot of set-up time and after the machine was set-up it made sense to make a lot of the same part. As Henry Ford famously put it: any color you want as long as it is black.

Our process eliminates much of this set up time and thus the advantages of large production runs. Our production paradigm harkens back to a earlier time when a craftsman would make one at a time. That is what we do, but using modern techniques. We are not the only company using this approach.

Indeed our sofabed supplier, American Leather, uses this same production paradigm to produce made to order upholstered furniture. Watch this video explaining their process.

The result of this is our ability to create cabinetry solutions crafted to the particular needs of our clients. Over this part 25 years we have produced a tremendous variety of work and below are some representative samples of completed projects.